Comparing Thermal Pads and Thermal Paste

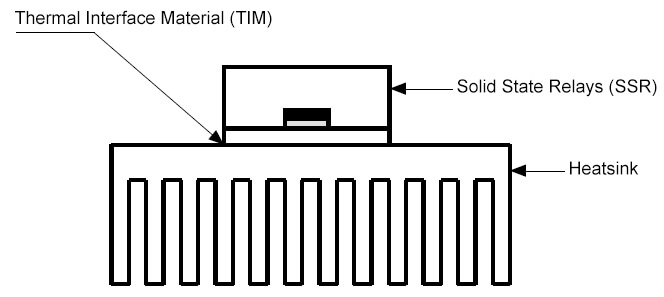

The surface of a Solid State Relay or a heatsink is not completely flat. If you install a Solid State Relay directly onto a heatsink, there will be imperceptible gaps between them. Because air conducts heat poorly, these gaps significantly reduce heat transfer. Therefore, an interface material with a high thermal conductivity is required to fill these gaps. This improves heat conductivity between the SSR and heatsink.

You can choose between using a thermal paste (or grease) and thermal pads. Which one is best for you? How do they differ and what are their advantages?

Thermal Paste

(also known an Thermal Grease or Phase-change Compound)

celduc ref. 5TH15000

This is a paste which can be directly applied to heatsinks. Of the two, thermal grease provides the best performance. Thermal paste is not easy to apply. It is used to counter Power Dissipation (Pd) for a 25<Pd<500W range.

Applying Thermal Paste:

- the surface must be clean, flat and smooth (roughness < 100 µm)

- the recommended paste thickness is between 80 and 120 µm, this means that when applying the grease, you must still be able to see the heatsink through it.

Thermal Pads

celduc’s ref. 5TH23000 for SC/SO ranges

celduc’s ref. 5TH24000 for SA/SU ranges

Thermal Pads are much easier to install than applying thermal grease. However, they aren’t as effective as a thin layer of thermal paste. For three-phase applications, for example, it is better to use thermal grease because thermal pads are limited in terms of power. The Power Dissipation (Pd) of thermal pads is in a 25<Pd<75W range.

celduc recommends aluminium thermal pads that have very good thermal performance and no change of state in the long term. On the market you can find thermal pads containing carbon (these are called SILPAD) but they are not good in terms of thermal performance.

Caution: If you uninstall a heatsink, clean the surface and replace the thermal pad.

Top tip:

For a product dissipating less than 20/25W (1 x 25 or 2 x 12.5 or 3 x 8.3A) a Thermal Interface Material (TIM) will not be sufficient in terms of cooling or service life. As it represents an additional cost, we advise using it only when it is absolutely necessary.